startechno40@yahoo.in - GST NO. : 05AIHPK8954C1Z8

- Send Email

4 piece (MOQ)

| Business Type | Supplier |

| Download |

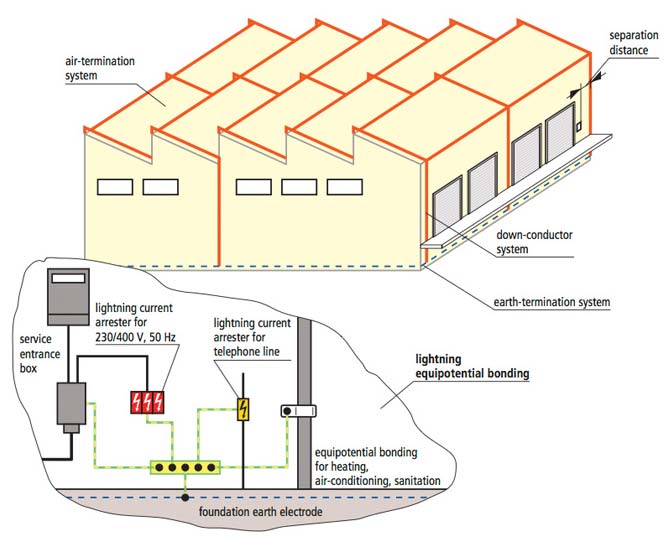

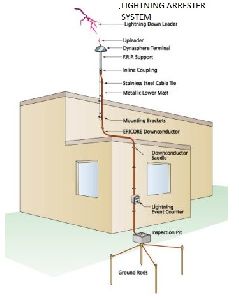

We are one of the recognized and trusted Suppliers of Earthing Protection System that is installed in commercial as well as residential sectors. Our Earthing Protection System is required to effectively manage the radio frequency emissions and electro magnetic interferences, to ensure steady reference potential for the accuracy of instruments and to provide protective discharge paths for lighting currents and short circuits. Our Earthing Protection System is highly reliable and widely demanded by the clients owing to its superlative advantages.

The Topic of Power system earthing does not get as much attention as the other topics of electrical engineering get. Probabliy, this is because of the fact that its importance its not realiged as the problems arising out of poor earthing, normally manifest only during fault conditions, which are generally for a short period, but may cause hauocs such as fire accidents, failure of equipments and inqury to personnel, disturbance in communication lines etc. And is not detected easily unless a thorough inuestigation is made. From our experience, it is felt that almost 50% of the problems faced in the power supply can be avoided if the earthing system is properly designed and maintained in good condition. With this is view it is necessary that the field Engineering realige and appreciate the importance of earthing in power system.

Requirement of Earthing

As a common man it is essential to understand the basic concept behind the making of this product. In an electrical circuit the most important component is earthing or grouding. The electrostatic discharge which is produced destroys the sensitive equipments and even disrupts the power supply, so it becomes important to take appropriate measures to eliminate them. The main objective of earthing is :

- To effectively manage the radio frequency emissions and electro magnetic interferences

- To ensure steady reference potential for the accuracy of instruments

- To provide protective discharge paths for lighting currents and short circuits.

Why Should we Opt For Superior Earthing?

Over the past few years the world has seen massive technological development in India. Advanced technology has given superior quality sensitive equipments which are being used in a range of domestic and industrial applications.

The safety of human beings is the prime concern of one and all, but apart from this concern even minor fault currents can damage the super sensitive and immaculately expensive equipments which can in turn affect the age and performance of the machinery.

The sophisticated equipments used in the current times demand superior quality in earthing as well. The age old method of GI pipe earthing and copper plate earthing which were carefully positioned amidst layers of salt and charcoal cannot cater ot the demands of the new generation machinery. Over past many years it has been noticed that the corrosion of metals and scarcity of moisture in and around earth pits lead to electrical short circuit, which eventually leads to loss of life and property.

Technical Comparison

|

Conventional Earthing system |

Newtron Earthing System |

|

Requires maintenance |

Requires no maintenance. Hence economical. |

|

Requires Re-Earthing after some reasonable period. |

Not requires to re-earthing for decades. |

|

Requires watering arrangement frequently. |

Requires no watering hence Economical. |

|

Limited life |

Unlimited life |

|

Watering arrangement requires pipe line, taps, etc. |

Requires no piping, taps, hence saving in material, labour, supervision & manpower etc. |

|

Not effectively useful in hard rock |

Useful in hardrock and offers resistance less than 0.50 hm. |

|

Requires standards pit size |

Pit size can be reduced hence reduce labour cost. |

|

Useful in special soil condition. |

Useful in any soil condition. |

|

Liable to get corroded early hence probability of breakage in earthing. |

No corrosion occurs hence no problem of breakage in earthing. |

|

In hardrock it is difficult to carryout earthing. |

Very easy to carryout in hardrock. |

|

Only one G.I./CI Pipe/Plate of particular diameter. |

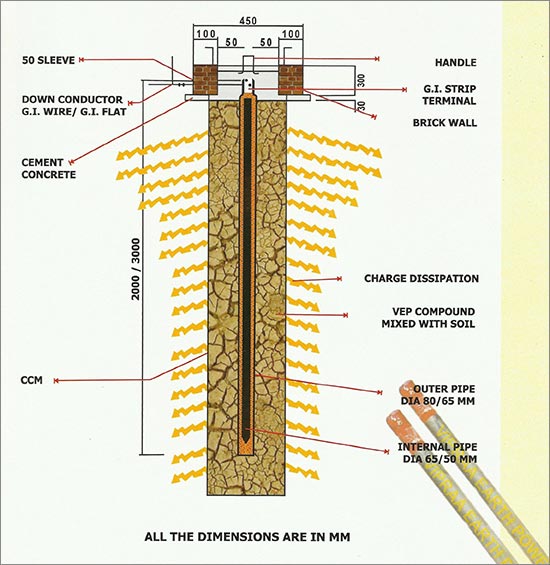

There are two GI pipes G.I. Strip Terminal with Dual pipe Technology |

|

It is liable to fast corrosion and subesquent decay of earthing pipe / plate |

There is absence of corrosion in Newtron Earthing System |

|

The Traditional Earthing system is in direct contact with soil. |

Newtron Earthing system is not in direct contanct with soil. |

|

Galvanization is not adequate. |

Galvanization is adequate |

|

Cost of the 15 to 20 plus years will be about three times more then the one time cost of Newtron Earthing system |

Cost Effective |

|

Salt Charcoal is used as Traditional Compound, as salt in highly corrosive electorlyte it corrodes GI/CI electrodes and then finally gets the high ohmic value |

Newtron Earthing System is non Corrosive, so there is not much variations in Ohmic value |

|

It requires much larger space and time to install the traditional earthing system. |

It requires very less space and time to install the Newtron earthing system. |

|

Traditional compound (Salt) uses gets washed away in rainy seasons and results as high ohmic value. |

The Newtron Compound is not soluble in water & it becomes part of soil around the Newtron earthing System. |

This in due course led to thorough research in the field of earthing in order to create a safe and dependable system of earthing. Finally Newtron has brought in a product which is perfectly designed and developed to meet all the requirements and drawbacks of the traditional system of earthing. Newtron has designed the G.I. Strip Terminal with Dual pipe Technology of earthing system which ultimately gives a much more stable, corrosion resistant, Sturdy, and competitively priced and maintenance free product.

Newtron Compound

Newtron earth system (Newtron) comes with compound named Newtron compound which has all the qualities of the ideal Newtron compound for an Earthing system. It can be easily compacted and when water is added to it, it can absorb up to thirteen times its dry volume. It consistently holds to its own shape and can adhere to any surface it touches. All these qualities resolve the problem of compatibility and soil/rod contact that are vital to any earthing system. The remarkable quality of Newtron compound ensures that it absorbs any available moisture and maintains it within itself, in contrary to surface appearances.

Main Benefits of Earthing Protection System

- Maintains moisture within the sphere of influence of Newtron earthing system. The Newtron Earthing system causes low soil resistance around the earthing system which thereby results in lower earth resistance, which cannot be otherwise obtained by use of conventional earthing system installation.

- It cathodic protection for the Newtron Earthing system.

- It enhances the soil conductivity of the surroundings thereby making it more effective for high fault, noise, ripples, harmonics, neutral to earth for unbalancing and lightning current dissipation.

- To further improve durability and performance the enhancement Newtron material has special application with non toxic enhancers.

Graph